| Price | USD$0.85/KG |

| MOQ | 1*20ft |

| Delivery Time | 15~25 days |

| Brand | IRONSTONE |

| Place of Origin | China |

| Certification | RMI(R-Mark Certification)/ AS4084-2012 / CE / ISO9001 |

| Model Number | CFR Model |

| Packaging Details | Plastic stretch film, corrugated paper, cartons, wooden bars, crates, and metal strips, etc. |

| Payment Terms | L/C, T/T |

| Supply Ability | 3000 Tons per month |

| Place of Origin | China | Packaging Details | Plastic stretch film, corrugated paper, cartons, wooden bars, crates, and metal strips, etc. |

| Dimension | H:1.5~3.0Mts,Depth: 0.45~1.2Mts, Width: 1~3.9Mts, Customizable As Request | Model Number | CFR Model |

| Supply Ability | 3000 Tons per month | Certification | RMI(R-Mark Certification)/ AS4084-2012 / CE / ISO9001 |

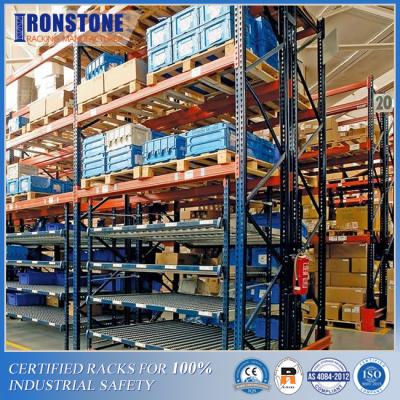

| Name | Gravity carton flow racking system | Brand Name | IRONSTONE |

| Payment Terms | L/C, T/T | Design | Inclined rails with rollers for semi-automated pallet movement |

| Components | Upright frame, beams, galvanized rollers, bracing | Price | USD$0.85/KG |

| Delivery Time | 15~25 days | Load Capacity | Light duty, medium duty and heavy duty |

| Minimum Order Quantity | 1*20ft | Features | Fast stock rotation with FIFO |

| Application | Carton, boxes, pallets storage and picking |

Carton flow is a form of shelving that uses a gravity-feed rear-load design. Each unit consists of one or more inclined runways. Merchandise is loaded in the rear of each runway. As an item is removed from the front, the item directly behind it slides forward in place of the previous one.

The

cargo

position

of

the

carton

flow

rack

is

arranged

by

rollers.

The

horizontal

position

of

the

inventory

end

is

higher

than

that

of

the

pick-up

end,

forming

a

top-down

inclined

plane.

Generally,

we

design

the

inclined

angle

of

about

5

degrees

in

the

horizontal

plane.

And

the

number

of

trays

on

each

level

will

be

designed

according

to

the

weight

of

goods

on

each

pallet.

Pallet

flow racking

system

details

| Rack Name | Gravity-taken pallet flow racking system with fast stock rotation |

| Rack Type | Dynamic flow with semi-automated stock rotation |

| Upright Section | Customized sizes, commonly used sections: 80*60, 90*60, 90*70, 100*70,120*95 |

| Beam Section | Customized sizes, commonly used sections: 80*50/100*50mm |

| Product Material | High Strength Steel/American Standard Steel |

| Load Capacity | Customized load capacity, commonly with 1000/1500kg per pallet load |

| Storage Layer | Customized, 2-6 Adjustable layers |

| Features | FIFO inventory rotation, fast and efficient stock management |

| Surface finish | Powder-coated and galvanized steel for corrosion protection |

Theory

Carton flow rack is one of the derivatives of the gravity flow rack. Its structure is similar to pallet rack, but the difference is that the roller rail is installed on the beam, and the rail is inclined 3 degrees to 5 degrees.

When working, the forklift will be used to carry the cargo to the loading port of the rack, and the cargo will slide automatically from the entrance to the other end of the loading port by using its own weight.

Notice

The fluent strip of the rack is directly connected to the beam and the support bar in the middle. The slope of the flow strip installation depends on the size and weight of the container and the depth of the shelf, usually 5%~9%. If the load is heavy, 3 to 4 flowing strips can be installed on one railway.

If the railway is long, a partition board can be used to separate it, and the brake should be installed at the pick-up end to slow down the cargo in order to reduce the impact.

Product Quality Control

We

know

that

quality

comes

from

details,

so

in

every

process

of

product

production

and

manufacturing,

we

have

strict

requirements

and

control.

♦

From

the

selection

of

raw

materials,

we

strictly

use

alloy

steel

material.

This

material

has

good

quenching

and

tempering

physical

characteristics.

Moreover,

the

material

itself

has

the

characteristics

of

high

strength

and

high

toughness,

so

the

products

made

of

this

material

also

have

such

characteristics.

♦

Product

manufacturing

process:

We

have

sophisticated

manufacturing

equipment,

(we

have

nearly

1,000

sets

of

precision

molds

for

different

parts,

and

each

part

has

a

separate

production

line)

in

the

production

of

products

by

one-time

forging

technology.

♦ Product

inspection:

We

have

more

than

30

sets

of

different

product

production

and

inspection

equipment

(we

have

complete

product

inspection

and

testing

equipment).

After

the

production

and

processing

of

products

are

tested

by

various

tensile

forces

and

loads

and

so

on.

The

products

will

not

go

out

until

they

pass

the

inspection.

♦ Product

labeling:

After

inspection,

it

will

be

marked

on

the

product

according

to

different

load

capacities

and

specifications.

♦ Product

notes:

For

each

product,

there

are

instructions

and

product

use

notes.